HYDROSPARK

BETTER!FASTER!CLEANER!

Empowering the sustainability

In the XXI century, among the numerous challenges humanity faces, the issue of sustainable energy supply emerges as an undeniable priority. This challenge is further accentuated by the growing global population and the consequent increase in energy consumption.

The energy revolution has already begun. We are witnessing a gradual shift from the unconditional use of fossil fuels to one where renewable resources increasingly gain market share, thus revolutionizing old paradigms.

Wind and solar power could easily provide enough energy to cover global energy demand many times over [M. Perez et al., 2022], but the intermittent nature of these energy sources obliges us to rethink and redesign our energy system.

What is needed is extensive development of seasonal energy storage technologies and energy conversion on a massive scale.

We are on the brink of a new industrial era, often called the “Third Industrial Revolution” (a term coined by Jeremy Rifkin), where the need for efficient energy carriers is paramount.

Hydrogen will play a pivotal role as one of the primary energy carriers. It can be used directly for energy production and storage or in the synthesis of alternative chemicals such as methanol, ammonia, steel, e-fuels, dimethyl ether, and more.

Hydrospark Technology

We’ve engineered a revolutionary manufacturing process that produces solid oxide cells 8 times faster.

Our innovative manufacturing technology is adaptable to all thin ceramic flat layers, ranging from dielectrics, solid state batteries, thermal barriers, electronic substrates, gas membranes, to various types of solid oxide cells, including metal-supported, electrolyte, and proton-conducting cells.

We are on the brink of a new industrial era, often called the “Third Industrial Revolution” (a term coined by Jeremy Rifkin), where the need for efficient energy carriers is paramount. Hydrogen will play a pivotal role as one of the primary energy carriers.

It can be used directly for energy production and storage or in the synthesis of alternative chemicals such as methanol, ammonia, steel, e-fuels, dimethyl ether, and more.

SOCs durability Improved

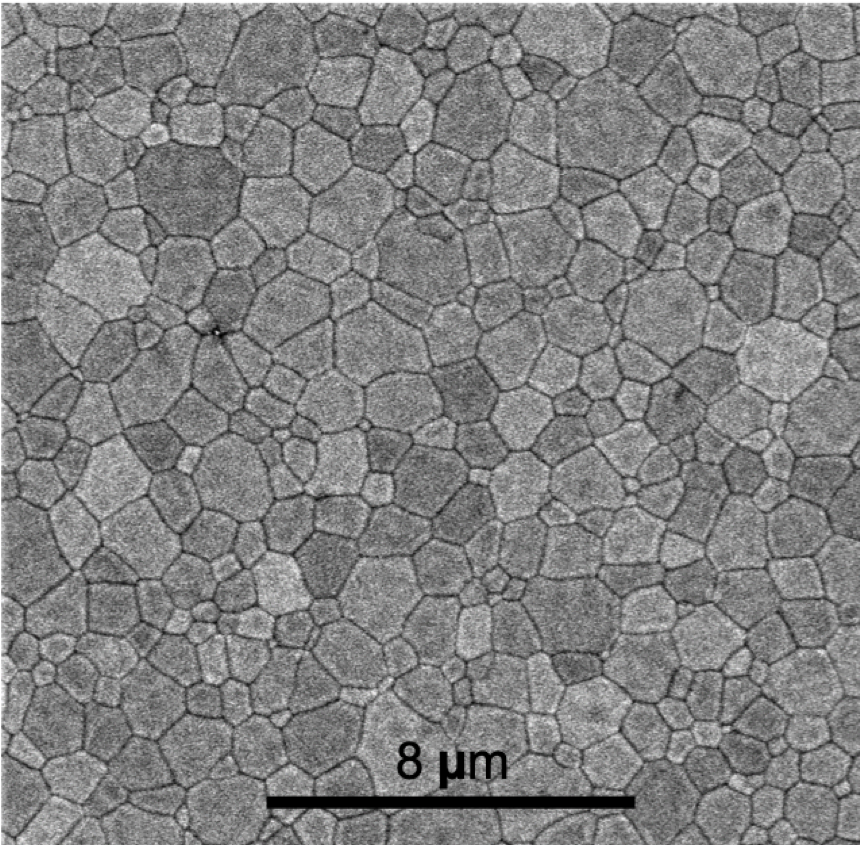

We developed a new methodology to make a denser electrolyte of solid oxide cells

SOCs manufacturing process made faster

We’ve engineered a revolutionary manufacturing process that produces solid oxide cells 8 times faster

We obtained our first patent

We patented a methodology to make solid oxide cells more durable

We filed our second patent

We filed a patent on our newly developed manufacturing process for half-cells

we will start our manufacturing line

The next milestone is securing sufficient funding to launch a production facility with an annual capacity of 1 million cells.

we will submit Our third patent

We have developed a new stack design that enables the replacement of damaged cells without affecting the integrity of the entire stack. Additionally, we have implemented a monitoring system capable of detecting potential malfunctions in advance.